How to design and install the FRP grille for the platform?

Release time:

2019-07-22

If the conditions are not allowed, the width of platform can be designed as much as possible to divide the whole plate size by the multiple of the inner grid modulus, so as to maintain the integrity o

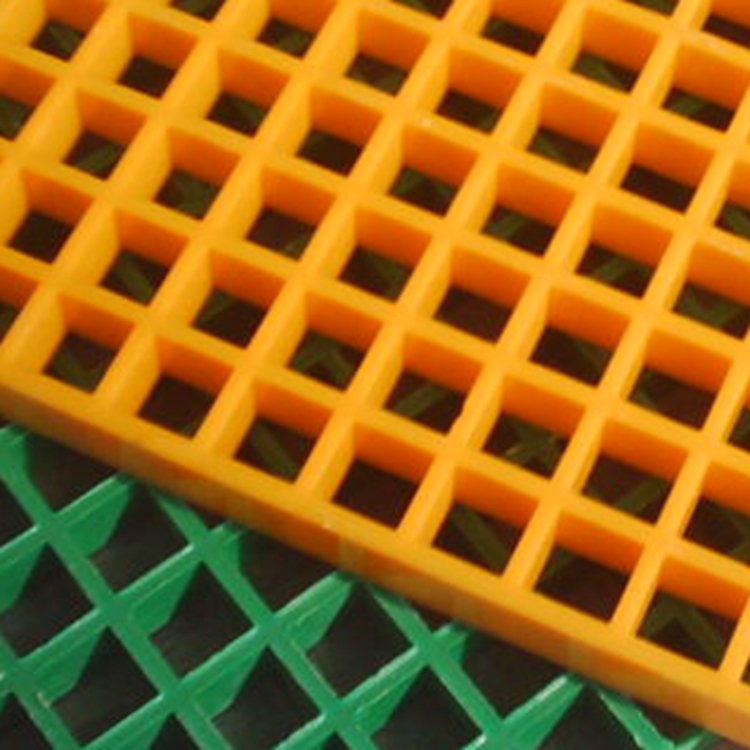

FRP grille, also known as FRP grille, originated in the United States in the 1970s. The advantages of FRP grille in overall performance such as transportation cost, installation and maintenance have gradually transformed it into a general-purpose material.

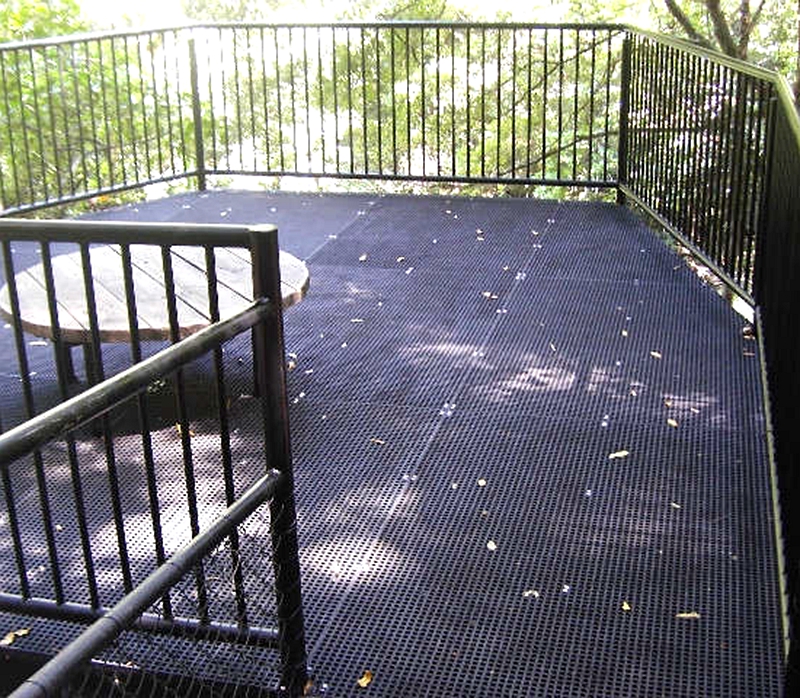

The application of FRP grille in platform: The design of platform width should make full use of the existing FRP grille width size. If the conditions are not allowed, the width of platform can be designed as much as possible to divide the whole plate size by the multiple of the inner grid modulus, so as to maintain the integrity of the material mechanical properties and reduce the cutting loss.

It is suggested that the design dimensions of platform width are as follows:

The FRP grille for platform needs to select the resin type, grille specification, thickness and surface type according to the requirements of environment, load and use occasion.

The corrosion resistance of FRP grille is determined by its raw material resin. Different resin types have different corrosion resistance.

The load capacity of FRP grids: 25 mm thick is about 1 ton, 30 mm thick is about 3 tons, 38 mm thick is about 6 tons, 50 mm thick is about 9 tons.

Surface type of FRP grille: smooth FRP grille sanded FRP grille pattern cover plate FRP grille.

The above is a summary of the FRP grids in the platform application design, hoping to help you understand some of the performance of FRP grids.

Related News