The model selection of pultrusion winding cable sleeve shall be based on the cross-sectional area of the cable

Release time:

2020-01-11

Cable sleeve is a hollow pipe used to protect wire and cable wiring in electrical installation, allowing wire and cable to be penetrated and replaced. The following describes the performance character

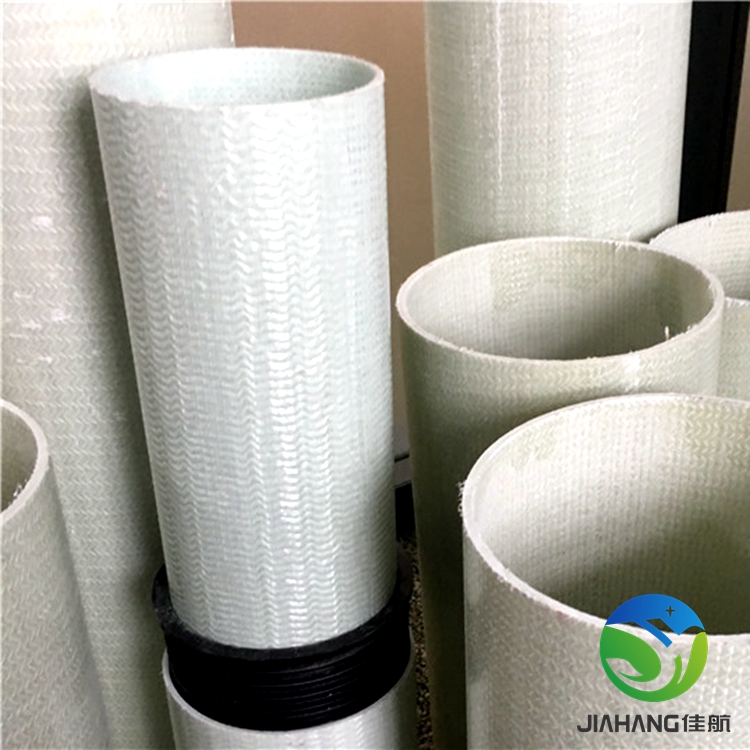

Cable sleeve is a hollow pipe used to protect wire and cable wiring in electrical installation, allowing wire and cable to be penetrated and replaced. The following describes the performance characteristics of a pull-down extrusion winding fiberglass cable sleeve.

[performance characteristics of pultrusion wound cable sleeve]

The cable sleeve of pultrusion winding can be used together with the special accessories to form a multi-layer and multi column cable pipe arrangement system according to different engineering requirements. The pultrusion winding cable sleeve is a pipe formed by die under stable high temperature and high pressure. Compared with the traditional pipe, due to the integrity and compactness of the fiber net, combined with the combination of longitudinal and circumferential, its longitudinal strength and circumferential strength are higher, so it has good resistance when impacted by external forces. Unlike the traditional pipe, it has weakness in a certain direction and is easy to be impacted by external forces It can be used in the environment of high temperature, humidity and salt alkali.

[how to select the cable sleeve for pultrusion and winding according to the cross-sectional area of the cable]

First of all, the outer diameter of the cable should be known. According to the outer diameter, the cross-section of the cable can be calculated to ensure that the cross-section area of the cable accounts for 40% of the inner section of the pipe. Such a pipe diameter is appropriate. It is roughly estimated that the inner diameter of the pipe should be 1.5-1.6 times of the outer diameter of the cable, and the coefficient of waste filling in the pipe should be about 40%.

Pultrusion winding cable sleeve is made of alkali free fiber and high-performance resin under high-pressure condition, with high product density and good insulation performance. The inner and outer surface layers are made of dense fiber braided layer. The product surface is no longer easy to crack like the traditional pipe, which can be used in the fields of telecommunication, electric power engineering, transportation, urban construction, etc.

Related News