Is the cable protection sleeve environmentally friendly?

Release time:

2019-12-25

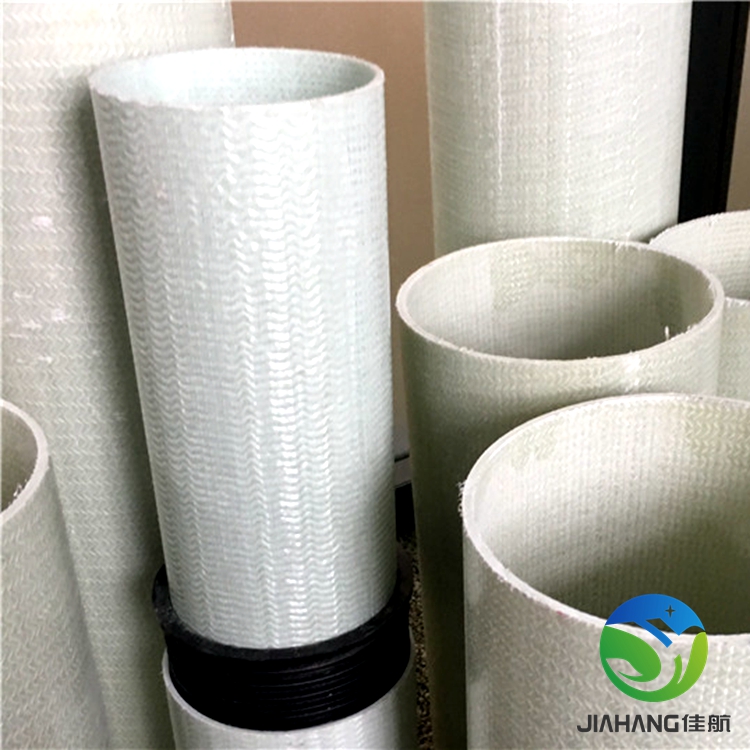

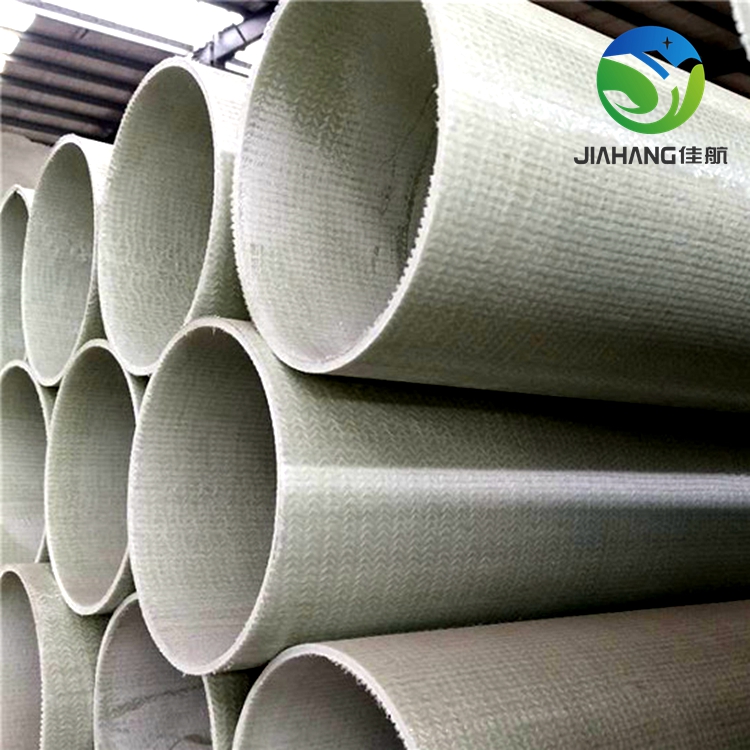

Pultrusion winding cable protective sleeve is a new kind of sleeve material, which is based on resin and reinforced by continuous glass fiber and its fabric. It is a kind of pipe which can be matched

Pultrusion winding cable protective sleeve is a new kind of sleeve material, which is based on resin and reinforced by continuous glass fiber and its fabric. It is a kind of pipe which can be matched with modern cable engineering construction by computer control winding process. The inside and outside of the pipe adopts dense fiber winding layer, and the surface is no longer like the traditional pipe.

The protective sleeve of pultrusion winding cable is formed by cross weaving and pultrusion of high-performance fiber in transverse and longitudinal direction, so as to improve the ring rigidity and tensile strength of the pipeline from the physical structure, so as to prolong the service life of the pipeline; on the other hand, the pultrusion winding cable pipeline has high requirements for raw materials, mainly using glass fiber with chemical molecule of silica, which can resist acid and alkali The main components come from quartz sand. The raw materials extracted from quartz sand return to the underground, which conforms to the natural law.

During the forming process of pultrusion winding cable protective sleeve, through the high-temperature curing process, the unsaturated polyester resin material in the process of transforming from liquid to high-temperature solid, styrene has polymerization and oxidation reaction, the chemical molecular structure has changed to polystyrene, which has no pollution. If the temperature resistant resin is used, the high-strength pultruded winding pipe can run for a long time at 120 ℃ and maintain good mechanical properties.

As a kind of composite pipe, pultrusion and winding fiber cable protective sleeve has many characteristics, such as light weight, good impact resistance, short molding cycle, high degree of design freedom, etc., and its in-process products are lightweight, comprehensive utilization of resources and other aspects of reducing carbon emissions.

Related News