Introduction to the forming process of GRP ground grid

Release time:

2019-12-23

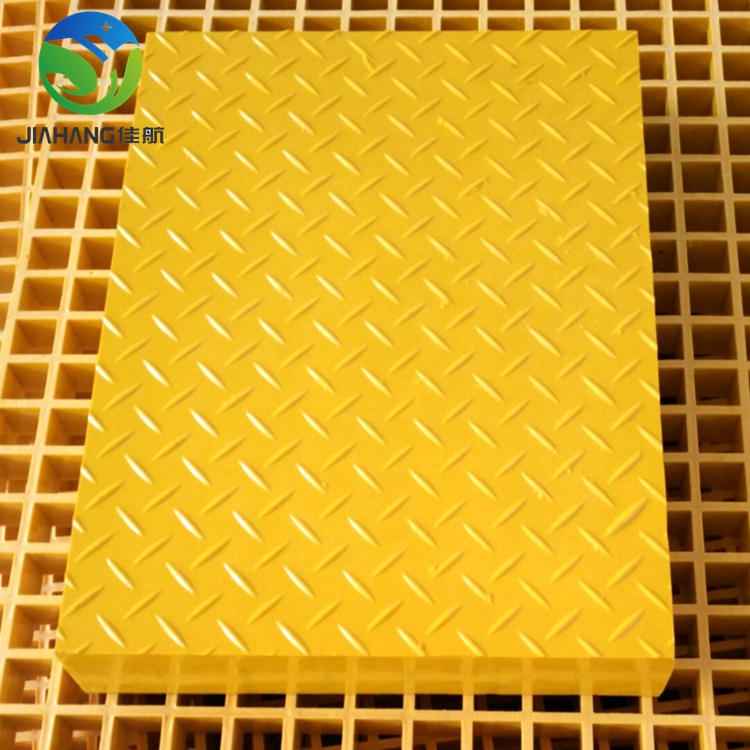

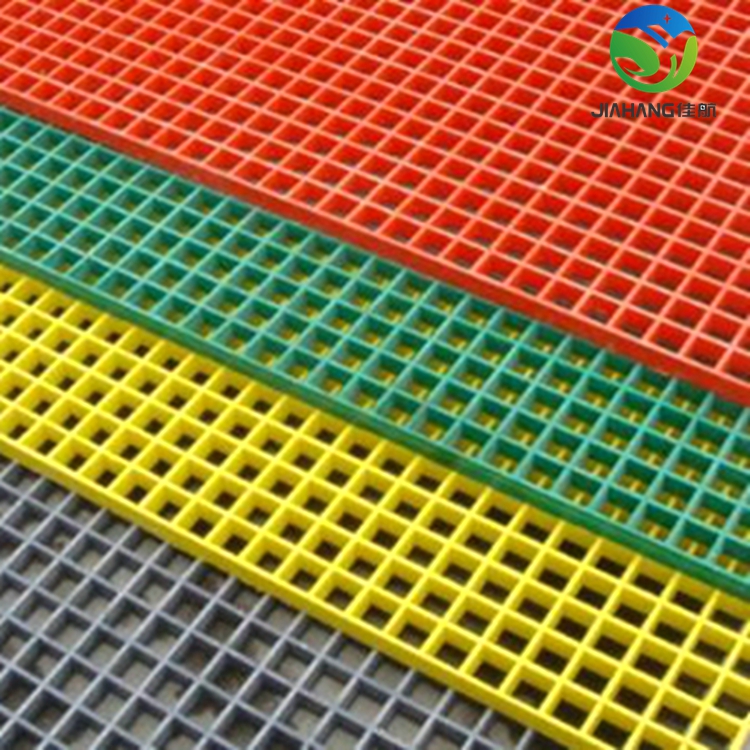

GRP ground grid is a kind of GRP plate with many regular rectangular and square spaces, which is made by molding technology. It can be divided into crescent, sand, biplane, flat grid, etc.

GRP ground grid is a kind of GRP plate with many regular rectangular and square spaces, which is made by molding technology. It can be divided into crescent, sand, biplane, flat grid, etc.

The designability of GFRP ground grid is reflected in the following aspects:

1. FRP ground grid can design various structural products flexibly according to the needs, such as anti-skid grid, closed pattern grid, small hole grid, sand grid, etc., which can make the grid have better integrity.

2. FRP ground grid can choose raw materials to meet the performance of products, such as: can be designed to resist corrosion, transient high temperature, special high strength, good dielectric and so on.

3. FRP ground grid can be flexibly selected according to the shape, technical requirements, use and quantity of products.

4. The GRP ground grid has simple technology and can be formed at one time, especially for the products with complex shape and less quantity that are not easy to form.

5. Common color classification of GRP ground grid: yellow, gray, blue, green, red, white, etc. (other colors can be customized according to the provided samples or reference Raul color card according to the card number.)

According to the forming process, GRP ground grid can be divided into common type, primary color transparent type, groove type, sand laying anti-skid type, double-layer small hole type, cover plate type, cover plate sand laying type, pultrusion type, which are mainly used in food processing workshop, aquaculture workshop, operation platform of chemical plant, stair pedal of corrosive workshop, drainage plate of car washing room, ditch cover plate on the road side, etc.

Related News