Instructions for use of FRP checkered cover plate

Release time:

2019-12-20

GRP patterned cover plate is a kind of load-bearing plate. Its main difference with GRP grid is that the former pays more attention to the role of sealing, while the latter is relatively more resource

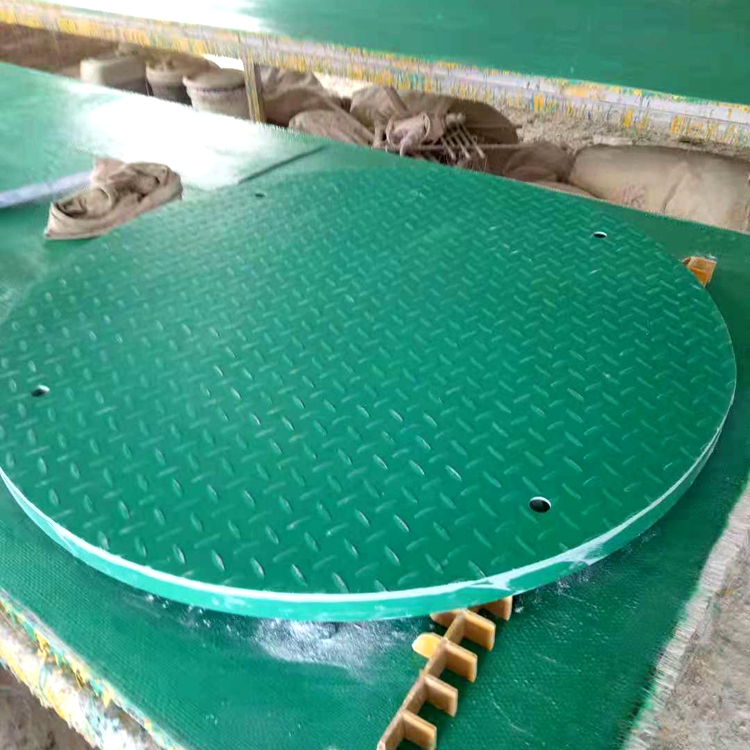

GRP patterned cover plate is a kind of load-bearing plate. Its main difference with GRP grid is that the former pays more attention to the role of sealing, while the latter is relatively more resource-saving. When GRP patterned cover plate is used as well cover plate, trench cover plate and cable trench cover plate, its main function is to prevent polluted gas from emitting into the air or polluting source liquid from evaporating, which is harmful to the environment Form pollution.

When the production of GRP checkered cover plate is completed, it is recommended to cut it before putting it into use. This is because the length and width of the standard GRP grid is 3.66 x 1.22m, which is relatively large, so that the GRP grid plate and checkered cover plate can not be fully integrated. If the application time is long, part of the two may be separated. Our manufacturer does not recommend the whole plate Using, as long as the reasonable incision can avoid this problem.

If it is necessary to use the whole plate of FRP pattern cover plate, it is necessary to reinforce the FRP cover plate. The detailed operation is as follows:

1. In order to avoid the separation, the edge of FRP pattern cover plate is fixed with FRP joint fastener.

2. If it is not cut, it is recommended to use the FRP pattern cover plate in the occasion with large pressure.

3. The fiberglass cover plate shall be inspected and maintained regularly.

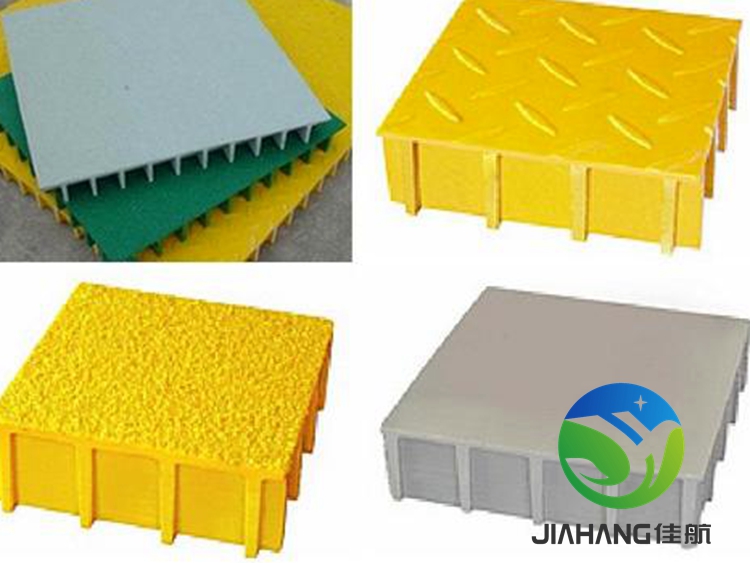

GRP patterned cover plate is a combination of GRP grid plate and patterned cover plate on the surface. Specifically, a layer of 3mm thick patterned surface is added on the surface of GRP grid. This patterned surface is made of pure resin, which is corrosion-resistant and flame-retardant, strong and non slip, light in weight, easy to install, maintenance free, insulation and other characteristics. It is often used in areas requiring airtight, for sewage treatment Facilities, can prevent corrosion and gas escape.

Related News