How to deal with the connection between the GRP arch cover plate and the cover plate?

Release time:

2019-11-30

The arch cover plate of sewage treatment plant is used for the sealing of sewage pool and oxidation ditch to prevent odor emission. An exhaust port is set on the arch cover plate of FRP to lead the od

The arch cover plate of sewage treatment plant is used for the sealing of sewage pool and oxidation ditch to prevent odor emission. An exhaust port is set on the arch cover plate of FRP to lead the odor out to the deodorization equipment through pipes. FRP is a stable non-metallic material, which can withstand the erosion of strong acid and alkali and water rust, and basically does not need maintenance.

Installation method of GRP arch cover plate in sewage treatment plant:

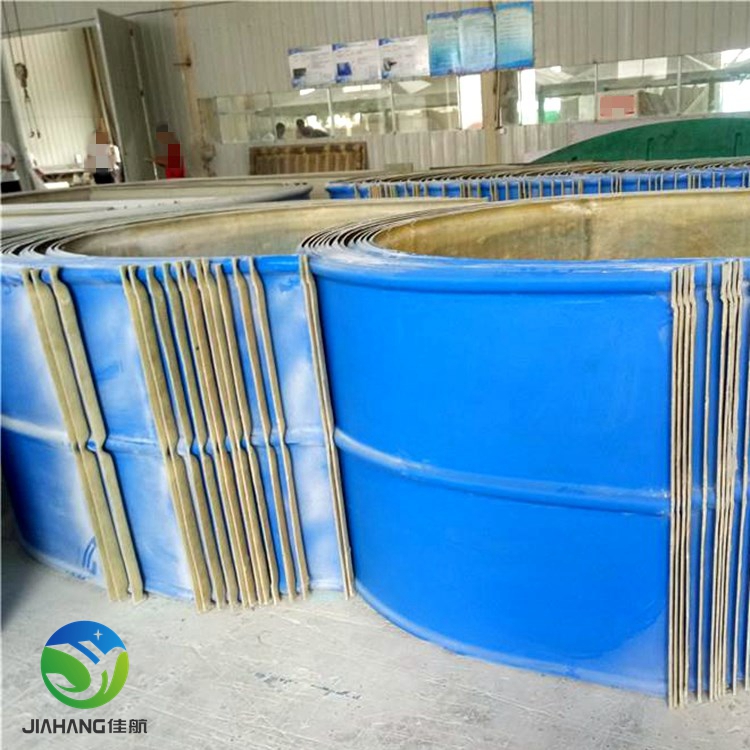

1. The cover plate and cover plate are connected by cover edge flange or cover edge type, and the gap is sealed with resin cement and glass silica gel to play a waterproof role.

2. The joint between the cover plate and the pipeline, and the joint between the pipeline and the pipeline shall be connected and reinforced with the resin glass fiber, and the thin glue mud seal shall play the role of waterproof.

3. M12 expansion bolt is used for the connection of cover plate and pool wall concrete base. Considering the vertical error of the trench wall plate during construction, the following two schemes can be adopted:

A) full length galvanized angle steel shall be set at the place of shelving.

B) customized according to the field measured data.

5. The FRP cover plates of each pool shall be assembled on site in blocks and numbers and laid in blocks.

6. The flange or compound connection part between blocks shall be perforated and connected with 304 stainless steel bolts above M10, adjacent to each other

The distance between the two bolts is 20cm.

7. Sealing and sealing shall be conducted on site between flange and flange or between multiple connections.

If the span of GRP arch cover plate is too large, the flat iron or angle steel should be embedded in the cover plate plane to further strengthen the large span cover plate. In the daily use process, the pipeline, pipe fittings, valves, etc. shall be inspected and maintained regularly to ensure the normal operation of the equipment.

Related News