What is the temperature resistance of GRP arch cover plate?

Release time:

2019-11-26

After the GRP arched cover plate of the sewage tank is sealed, it can effectively prevent environmental pollution caused by gas volatilization. Generally, the GRP arched cover plate of the sewage tank

After the GRP arched cover plate of the sewage tank is sealed, it can effectively prevent environmental pollution caused by gas volatilization. Generally, the GRP arched cover plate of the sewage tank is used for sealing.

Introduction to raw materials of GRP arch cover plate for sewage tank:

Reinforced material: glass fiber reinforced material;

Matrix material: special thermosetting resin, heat and cold resistance, anti-aging and other additives

Auxiliary materials: flame retardant, reinforcing agent, water resistant agent, gelling agent, UV resistant agent, etc

Parameter introduction of GRP arch cover plate for sewage pool:

Technical parameters: tensile strength: ≮ 200Pa impact strength: ≮ 20j / cm2 bending strength: ≮ 150pa molding density: ≮ 1800kg / cm3

Physical properties: Barcol hardness: ≮ 50 roughness: 0.0084 fracture elongation: 0.8% wear resistance: ≥ 99.98%

Poisson coefficient: 0.3 wear allowance: ≮ 1.5 -- oxygen index: > 36 temperature resistance: - 50 ~ 110 ℃

Flame retardant performance: in accordance with astm-e84 (flame burning rate less than 25)

Anti organic compounds: including methanol, ethanol, hydrogen sulfide, oil and gas, etc

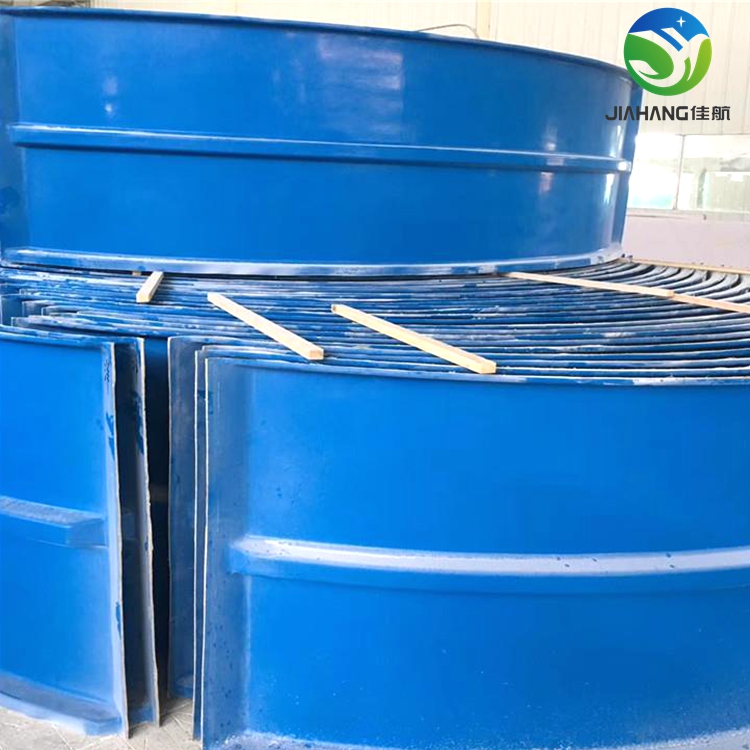

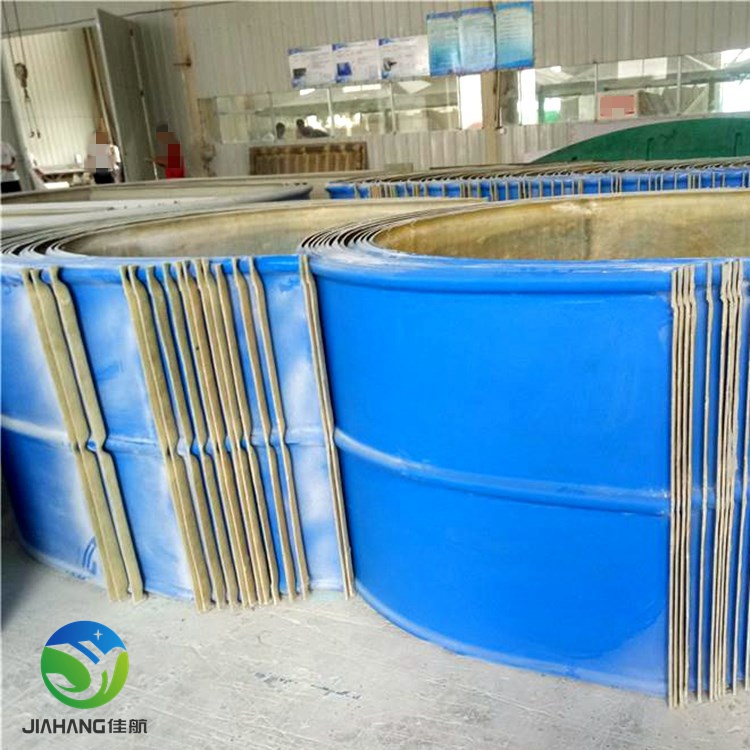

The forming process of GRP arch cover plate for sewage tank is introduced

Production process: mold sand blasting pouring one-time molding;

Finished product composition: anti-corrosion layer, additional layer and climate resistant layer;

The special GRP arched cover plate for sewage pool adopts special structural form, which has good integrity after installation, no support, good wind resistance, snow resistance and maintenance load, etc. the outer surface of the cover plate has a uniform rubber coating layer, with smooth surface, no cracks and uniform color. The resin content of the cover plate is more than 70% of the resin layer, 55% of the structural layer, and composite material The curing degree shall not be less than 80%; observation window and access door can be reserved on the arch cover plate to facilitate the maintenance of workers and not affect the normal operation of the equipment.

Related News