Is the FRP grille well installed? How is the FRP grille connected?

Release time:

2019-07-21

Some friends are not familiar with the installation of FRP grille. The following edition will introduce some matters needing attention in the installation of FRP grille for you.

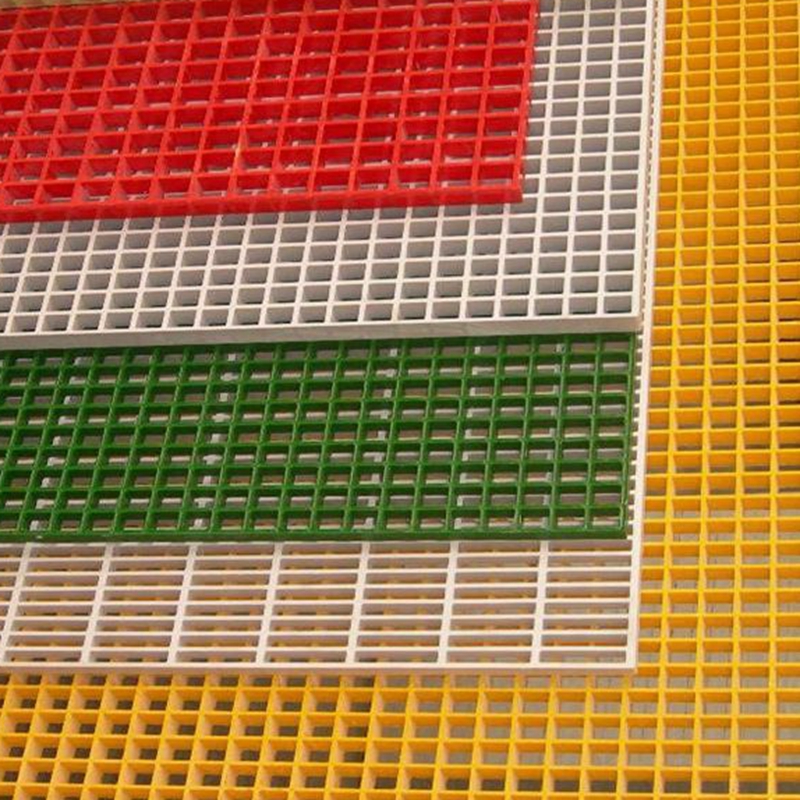

FRP grids are made of high density resin and fiberglass as the main raw materials, which are moulded after high temperature. They have the characteristics of corrosion resistance, aging resistance and wear resistance. FRP grille can be used as fire-proof refractory, insulating material, anti-skid material and compressive material. Some friends are not familiar with the installation of FRP grille. The following edition will introduce some matters needing attention in the installation of FRP grille for you.

1. Customized FRP grilles

According to their own requirements to customize the corresponding grille products, such as different hole sizes, different shape sizes, different load requirements, etc., can largely reduce the loss caused by cutting to a lower level, thereby saving costs.

2. FRP Grille Entry Inspection

Before installation, the FRP grille shall be checked and accepted according to the design requirements of the drawings to check whether the dimensions are qualified and the unqualified products are not used in this project.

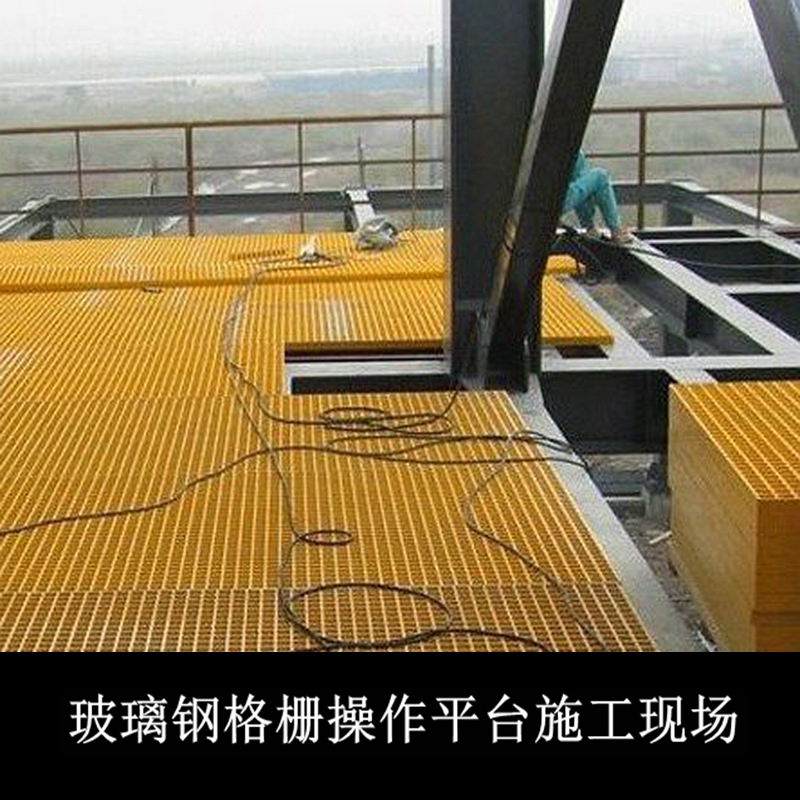

3. Determining the installation sequence of FRP grids

Before installing the FRP grille, the number of the grille should be given in conjunction with the drawings, and the installation sequence and location of the grille should be determined, so that no mistakes can be made and the installation time will be shortened. The installation process of FRP grille needs to be laid from the first layer of steel ladder to all around, which is the passage between the upper and lower platforms. It can not work on the upper platforms until the steps are laid.

4. Fixed FRP grilles

Fasteners should be used to fix each grille (the number of grille clamps per grille should not be less than 4). One grille plate should be fixed. No stationary grille plate is allowed to work, and temporary protective measures are allowed to be dismantled.

5. FRP grille stacking is strictly prohibited

FRP grids should not be stacked on steel beams, and the stacking height should not exceed 1.2m after installation. This is because a large number of grids will cause deformation or even collapse of the laid grids. On the other hand, disorder will also affect the installation progress.

6. Management of Tools in the Installation Process of FRP Grilles

During the installation of FRP grille, operators should put small tools into tool bags, and do not allow small tools and accessories (hammer, wrench, crowbar, welding rod, etc.) to be placed directly on the grille to prevent falling objects from injuring people. In the process of operation, site cleaning should be carried out. Tools and cut metal materials can not be stacked near the opening of the grille in the process of installation or demolition. Remaining materials at the corner should be recovered in time to prevent falling objects from hitting and scalding the skin.

7. High-altitude grille construction is not allowed in bad weather. If necessary, certain anti-skid and communication measures should be taken to ensure good sight.

Above is the summary of FRP grids in the installation operation of the seven points to be noted, I hope to help friends correctly and safely use FRP grids.

Related News