Follow-up treatment of semi-finished FRP grids

Release time:

2019-07-13

When FRP grille comes out of the mould, it belongs to semi-finished product and can't go out of the factory. This is because after it comes out of the mould, it has grooves. The grooves themselves wil

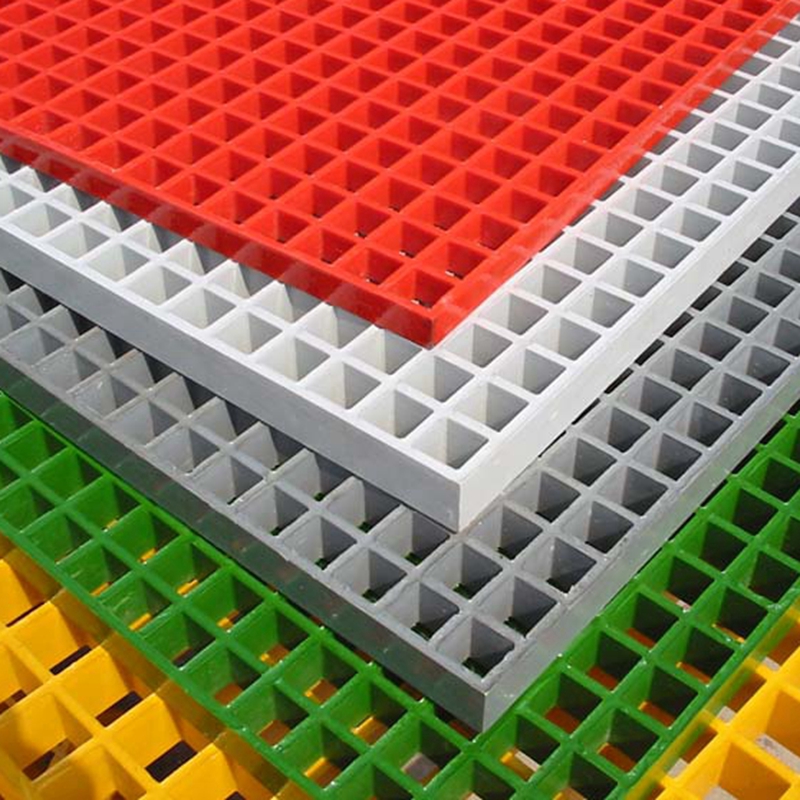

In fact, FRP grilles are very common in our life, especially in the fields of petroleum, chemical electronics, power, paper industry, and so on, as well as in drilling platforms and walkways. FRP grilles refer to a kind of plate formed by uniformly pouring resin mixture into the mould by using the moulding process.

When FRP grille comes out of the mould, it belongs to semi-finished product and can't go out of the factory. This is because after it comes out of the mould, it has grooves. The grooves themselves will not bear the load. If it is not polished, it will be even less neat and difficult to see after being pressed by heavy objects in the later period. In addition, it may be because the resin is not immersed in fiberglass, some pinhole-sized pores exist, which need to be treated to make the fiberglass grille more beautiful in front of customers. So, how does the FRP grille manufacturer handle the semi-finished products? Overall, this requires four steps, as follows:

1. After the FRP grille comes out of the mould, the upper surface is grooved. The groove thickness is about 1mm-2mm. It needs to be lifted onto the polisher and polished once. After polishing by a polisher, the upper surface will be polished flat or the groove is not obvious.

2. After polishing, the dust on the surface of FRP grille should be washed with high-pressure water gun, including the right corner of the inner grille. Rinse and dry. It should be noted that if there are too many air holes in the grille, it needs to be repaired with the matched thick material and then sprayed after repairing.

3. After the grille is dried, there will be white polishing marks on the surface. It is necessary to dip the varnish in the drum and roll it once, so that the original color of the grille surface can appear, or the surface can be sprayed with resin, so that it is more uniform and the effect is better.

4. After the surface treatment of the grille, it is necessary to cover the grille with plastic film to prevent dust and foreign bodies from falling on it.

After these four steps, FRP grille meets the factory standard. After packaging with cardboard, packing tape and so on, FRP grille can leave the factory.

Related News