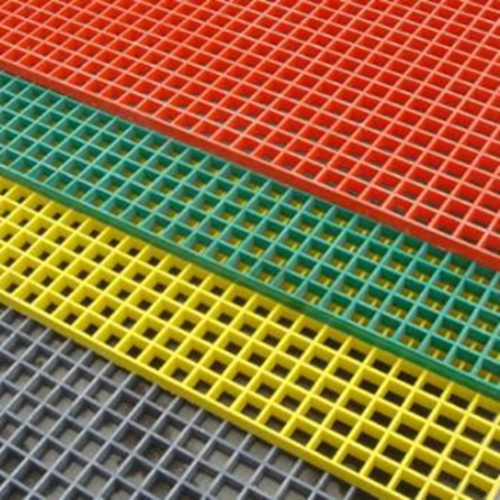

Key Technologies for Production of High Quality FRP Grids

Release time:

2019-07-11

When many friends consult with FRP grids, the first concern is the price, which is undoubtedly a dangerous move. The quality of FRP grids is the most important concern for us. Good quality FRP grids c

When many friends consult with FRP grids, the first concern is the price, which is undoubtedly a dangerous move. The quality of FRP grids is the most important concern for us. Good quality FRP grids can be guaranteed to a great extent in terms of service life or production safety, so the production of high-quality FRP grids is very important. What's the key?

1. The quantity of raw materials and the mismatch of raw materials will directly affect the later performance, especially durability and flame retardancy. If less flame retardant is released, the flame retardant effect will be poor.

2. Resin pouring. In the process of resin pouring, resin is poured while glass fiber yarn is pressed. If the glass fiber is impregnated badly, the bubbles in the resin can not be discharged. The defects such as bleaching and bubble cracking are easy to occur in the formed grille, which will reduce the corrosion resistance and mechanical properties of the grille.

3. Heating temperature and time are different from other hand paste products. A small amount of initiator is added to the moulded grille resin castable, which can not be cured at room temperature, but needs to be heated to 80-120 degrees. Curing temperature has a great influence on the properties of the grid, especially the mechanical properties. The mechanical properties do not increase with the increase of temperature, but according to different resins, there is an optimum temperature value for the mechanical properties of the grid. The higher the temperature, the lower the mechanical properties. This is related to the exothermic peak and curing temperature of the resin. Curing temperature also affects the position and peak value of exothermic peak of resin. The higher the curing temperature, the higher the peak value, the higher the curing temperature will cause grille burns and destroy the bonding interface between resin and glass fiber. Short curing time will result in incomplete curing, and too long curing time will not improve the performance of the grid.

There are many other factors that affect the quality of FRP grids. You are welcome to add them.

Related News